In today's hyper-competitive manufacturing landscape, precision isn't just a goal; it's the bedrock of quality, reliability, and customer satisfaction. As components become more intricate and tolerances shrink, the demand for sophisticated quality control (QC) processes has surged. Optical measurement technology, including solutions from leading Optical Comparators Suppliers, stands at the forefront of this revolution, offering non-contact, high-accuracy inspection solutions crucial for maintaining stringent standards. Choosing the right optical measurement tool is no longer a simple procurement decision; it's a strategic investment that directly impacts production efficiency, reduces waste, and safeguards brand reputation. This guide explores five leading solutions in the optical measurement arena for 2025, including contributions from Optical Comparators Suppliers, comparing their strengths to help manufacturers identify the best fit for their specific operational needs and quality objectives. From benchmark precision to high-speed automation, understanding these technologies is key to unlocking the next level of manufacturing excellence.

Table of contents:

Easson Digital Optical Comparator: Setting the Gold Standard in Precision Metrology

Video Measuring Machines (VMMs): Automated Precision for Complex and High-Volume Parts

Methods Machine Tools 500 Series: Reliable Optical Comparison from a Trusted Supplier

VisionXinc High-Performance Comparators: Optimizing Speed and Integration in Production

Keyence Image Measurement Systems: The Digital Frontier of High-Speed Inspection

Easson Digital Optical Comparator: Setting the Gold Standard in Precision Metrology

When the absolute highest degree of accuracy is non-negotiable, the Easson Digital Optical Mechanical Optical Comparator consistently emerges as an industry benchmark. Easson has cultivated a reputation built on delivering exceptional precision through robust engineering and sophisticated digital integration. This tool is specifically designed for manufacturers who require meticulous verification of complex profiles and geometries, where even sub-micron deviations can be critical.

The core strength of the Easson comparator lies in its synergy between high-quality optics and advanced digital readout (DRO) systems. The optical system projects a highly magnified, distortion-free image of the workpiece onto a precisely graduated screen. This allows operators to visually inspect intricate features, edges, and surface characteristics that might be impossible to assess with traditional contact measurement tools. Coupled with Easson’s renowned DRO technology, measurements become faster, more intuitive, and significantly less prone to human interpretation errors. The high-resolution display provides clear visuals, while the intuitive controls streamline the entire measurement workflow.

- Key Advantage: Uncompromising Precision:Easson systems are engineered for accuracy that often pushes into the sub-micron range. This makes them indispensable for quality control in sectors like aerospace, medical device manufacturing, precision machining, and electronics, where failure is not an option. Verifying complex part profiles against CAD overlays or tolerance bands becomes a reliable process. The function as an advanced optical comparator profile projector is central to its capability.

- Key Advantage: Enhanced User Experience:The integration of powerful digital interfaces simplifies complex measurement tasks. Features like automatic edge detection (in some models), geometric function calculations, and data output capabilities reduce manual effort and minimize the potential for operator error, leading to more consistent QC results.

- Key Advantage: Industrial Durability:Recognizing the demands of modern manufacturing, Easson builds its comparators for continuous, heavy-duty operation. Robust construction ensures longevity and reliable performance even in high-volume production environments, safeguarding the initial investment over many years. Manufacturers looking for reliable equipment, potentially considering digital optical comparator machine wholesale purchases for multiple lines, value this durability.

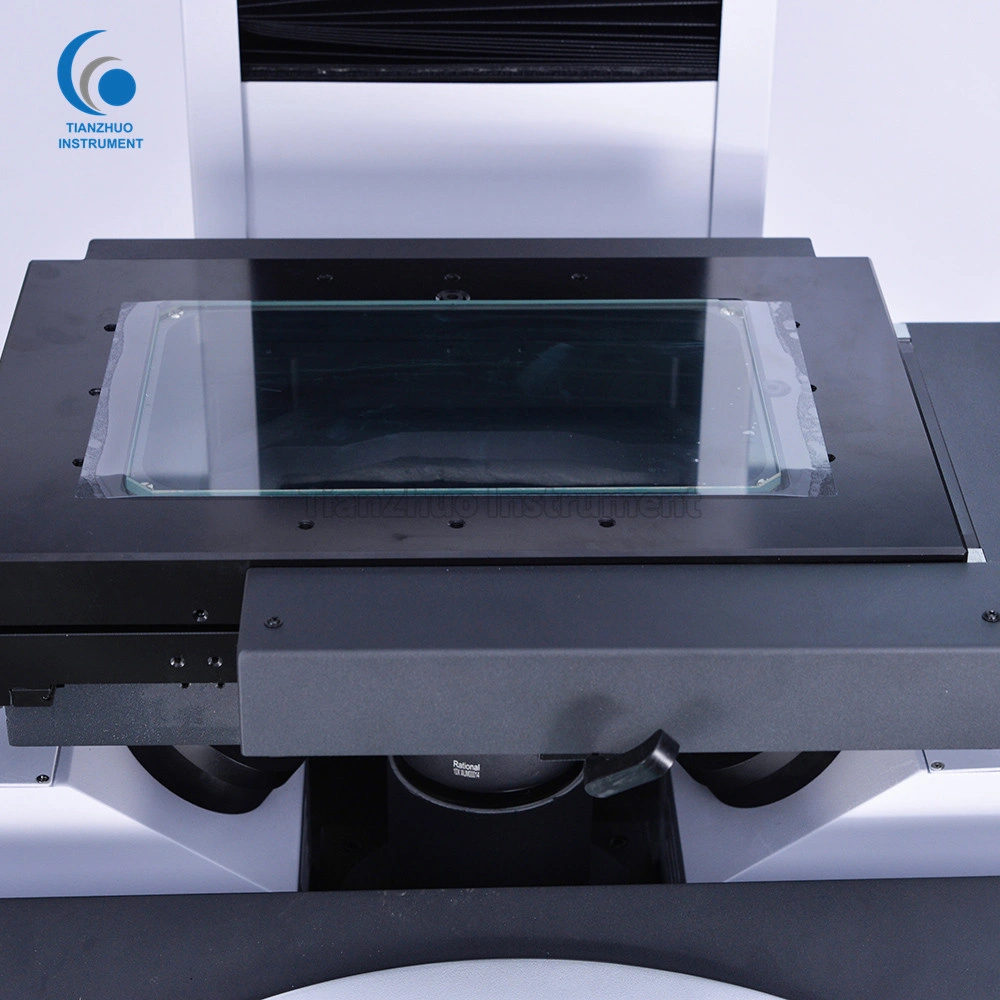

Video Measuring Machines (VMMs): Automated Precision for Complex and High-Volume Parts

https://www.video-measuringmachine.com/

Video Measuring Machines, often referred to as VMMs or Vision Measuring Systems, represent a significant evolution in optical metrology, particularly suited for inspecting large, complex parts or managing high-throughput inspection requirements. Instead of relying solely on a projected profile, VMMs utilize a high-resolution camera coupled with powerful magnification optics and sophisticated image processing software.

These machines excel where automation and data analysis are paramount. They can automatically detect edges, measure geometric features, compare measurements against digital CAD models, and generate comprehensive inspection reports with minimal operator intervention. The system typically involves a motorized stage that moves the part beneath the camera, allowing for the automated measurement of multiple features or even entire batches of components. The magnification capabilities often surpass traditional comparators, enabling detailed inspection of very small features.

- Key Advantage: High Magnification and Detail:VMMs offer variable and often significantly higher magnification levels compared to standard comparators, making them ideal for inspecting micro-features, surface textures, and intricate component details common in electronics or medical industries.

- Key Advantage: Automation and Speed:The integration of cameras, motorized stages, and intelligent software enables fully automated measurement routines. This drastically reduces inspection time per part, increases throughput, and ensures high repeatability, making VMMs perfect for high-volume production lines where speed and consistency are critical. Their ability to function as an automated optical comparator profile projector for complex shapes is a major benefit. Specific applications, like using it as a profile projector for cables to check insulation thickness or conductor concentricity, are easily automated.

- Key Advantage: Data Integration and Reporting:VMM software often includes powerful tools for statistical process control (SPC), report generation, and data archiving. This facilitates better process understanding, easier compliance documentation, and improved quality trend analysis.

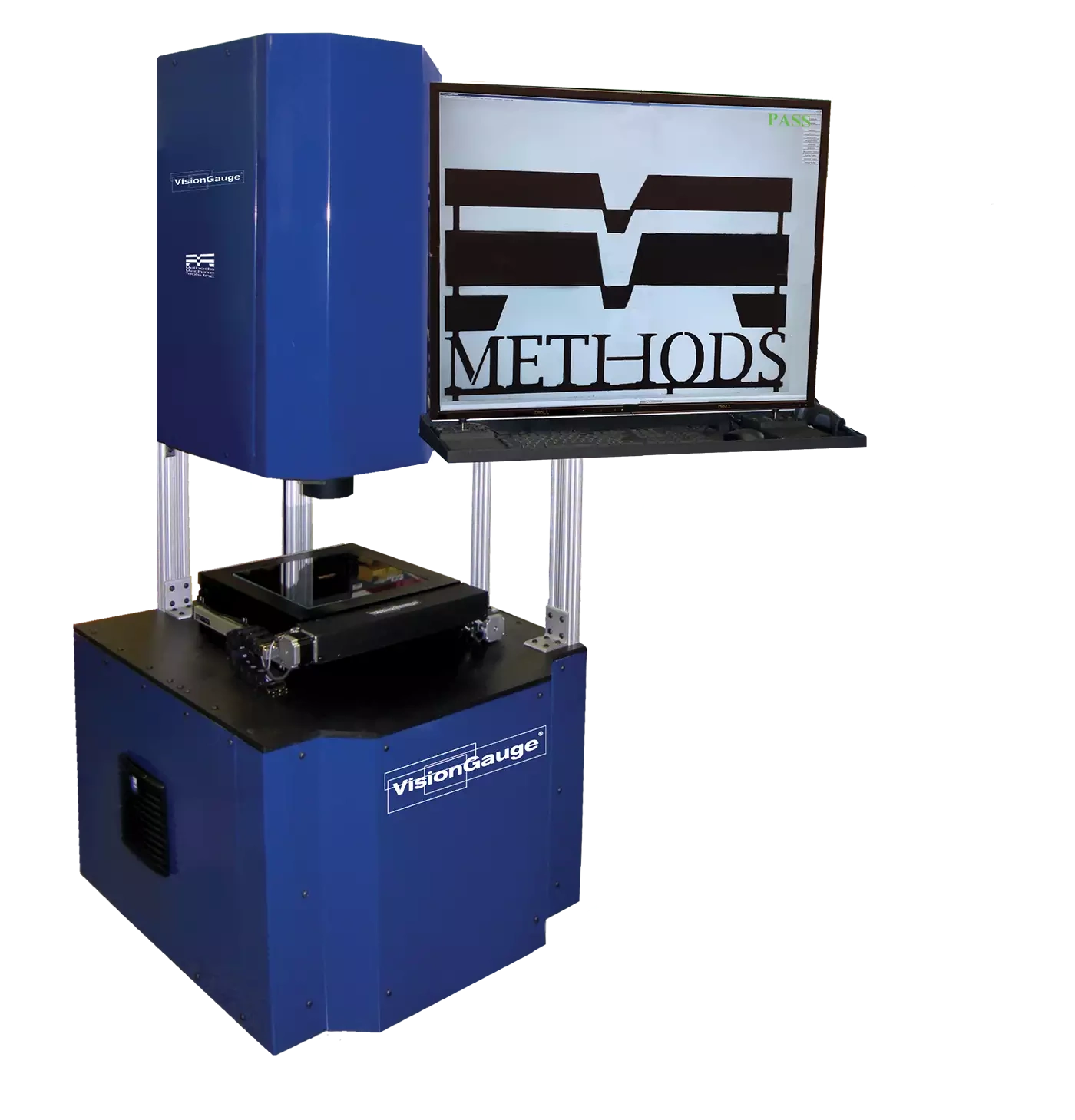

Methods Machine Tools 500 Series: Reliable Optical Comparison from a Trusted Supplier

https://www.methodsmachine.com/machines/500-series/

Methods Machine Tools is a well-respected name in the manufacturing technology space, known for providing robust and reliable equipment. Among their offerings are the 500 Series optical comparators, designed to deliver accurate and efficient measurement solutions tailored for demanding industrial environments. These tools blend traditional optical comparison principles with modern enhancements for improved usability and accuracy.

The 500 Series is positioned as a versatile workhorse, adaptable to a wide range of measurement tasks across various industries. They emphasize build quality and dependable performance, ensuring that manufacturers receive consistent results day after day. While perhaps not always pushing the absolute cutting edge like some specialized systems, they represent a solid, reliable choice from established Optical Comparators Suppliers.

- Key Advantage: Flexibility and Reliability:Methods' comparators are engineered to handle diverse measurement needs. Their robust design ensures they can withstand the rigors of the shop floor, providing reliable service for years. This adaptability makes them suitable for industries like automotive, aerospace, and general precision engineering.

- Key Advantage: High Accuracy for Manufacturing:These systems provide the high-precision measurements necessary to ensure components meet strict manufacturing tolerances. The clear optics and stable structure contribute to accurate visual inspection and dimensional measurement using the integrated screen and DRO or overlay charts. They serve effectively as a traditional optical comparator profile projector.

- Key Advantage: Supplier Support and Expertise:Choosing Methods Machine Tools often means access to established support networks and application expertise, which can be valuable for integration, training, and long-term maintenance.

VisionXinc High-Performance Comparators: Optimizing Speed and Integration in Production

VisionXinc focuses on delivering high-performance digital optical comparators specifically engineered to enhance quality control processes within high-volume production settings. Their systems are characterized by speed, reliability, and ease of integration, aiming to streamline inspection workflows and minimize production downtime.

These comparators leverage digital technology to provide fast readings and often incorporate features designed for quick setup and operation. The emphasis is on maximizing throughput without compromising the accuracy required for effective QC. VisionXinc positions itself as a provider of practical, performance-oriented solutions that readily fit into existing manufacturing ecosystems. As experienced Optical Comparators Suppliers, they understand the pressures of modern production.

- Key Advantage: Fast and Reliable Operation:VisionXinc systems are optimized for rapid measurement cycles. Features contributing to speed might include intuitive software, quick stage positioning, and efficient data capture, helping to prevent inspection from becoming a bottleneck.

- Key Advantage: Seamless Integration and Adaptability:These comparators are often designed with integration in mind, making it easier to incorporate them into existing production lines or automated QC cells. Their adaptability allows them to handle various parts and measurement routines efficiently. For businesses scaling up, inquiring about digital optical comparator machine wholesale options could be beneficial.

- Key Advantage: Enhanced Workflow Efficiency:By focusing on speed and ease of use, VisionXinc tools aim to improve overall workflow efficiency. Faster inspection means quicker feedback to the production process, enabling faster corrective actions if deviations are detected. Their role as an optical comparator profile projector is executed with an emphasis on speed.

Keyence Image Measurement Systems: The Digital Frontier of High-Speed Inspection

Keyence is a global powerhouse in automation and inspection technology, renowned for its cutting-edge digital measurement solutions. While not traditional optical comparators projecting a profile onto a screen, their Image Measurement Systems (like the IM Series) fulfill a similar QC function using advanced digital image processing technology and represent a significant trend in modern metrology.

These systems capture a wide-field image of the part and utilize sophisticated software algorithms to identify and measure potentially hundreds of features simultaneously, often in just a few seconds. The emphasis is squarely on speed, automation, and ease of use. The operator simply places the part on the stage and presses a button; the system handles the rest, from feature recognition to measurement and data logging.

- Key Advantage: Unparalleled Measurement Speed:Keyence systems are exceptionally fast, capable of measuring numerous dimensions on multiple parts simultaneously within seconds. This makes them ideal for 100% inspection in very high-volume production environments where traditional methods would be far too slow.

- Key Advantage: Extreme Ease of Use:Designed for simplicity, Keyence systems require minimal operator training. The place-and-press operation significantly reduces variability and the potential for human error, ensuring consistent measurement results regardless of operator skill level.

- Key Advantage: Advanced Image Processing:Leveraging sophisticated algorithms, these systems can reliably measure complex features and provide pass/fail judgments automatically, along with comprehensive data logging for traceability and analysis. They offer a digital alternative to the visual checks done on an optical comparator profile projector.

Selecting the optimal optical measurement tool is a critical decision for manufacturers aiming for excellence in 2025 and beyond. The choice hinges on specific application requirements, production volume, budget, and the level of precision demanded. Whether the priority is the benchmark accuracy of a dedicated digital optical comparator, the automated prowess of a Video Measuring Machine, the reliable performance offered by established suppliers like Methods Machine Tools, the production-line speed of VisionXinc, or the revolutionary digital approach of Keyence, a solution exists to meet nearly every need. Investing wisely in these technologies empowers manufacturers to enhance product quality, streamline operations, reduce costly errors, and ultimately build a stronger competitive advantage. For manufacturers prioritizing uncompromising precision and robust reliability in their optical measurement strategy, exploring the advanced capabilities offered by easson is a crucial step toward achieving production excellence.

No comments:

Post a Comment