In the world of metal processing, particularly with precious metals like gold and silver or high-value industrial metals like copper, profit margins are defined by precision. Every gram of material, every speck of dust, holds tangible value. Yet, a silent and persistent thief operates in many workshops and refineries: material loss. This isn't a single, dramatic event, but a slow, cumulative bleed caused by inefficient processes, outdated technology, and overlooked operational details. The difference between a thriving business and one that struggles to stay profitable often lies in its ability to control this waste. But what if you could not only plug these leaks but also transform your entire operation into a model of efficiency, profitability, and environmental responsibility? The solution lies not in working harder, but in working smarter with technology designed to preserve every last gram of your valuable material. A reliable granulating machine supplier can be an essential partner in this transformation, providing advanced tools that minimize material loss while maximizing operational efficiency. This article will take a deep dive into the hidden costs of material loss in metal granulation. We will explore where and why this waste occurs, how modern technology and a trusted granulating machine supplier provide a definitive solution, and what this means for your bottom line and the planet..

Table of contents:

Where Does Your Precious Metal Go? Pinpointing Material Loss in the Processing Chain

The Technological Shield: How Modern Granulators Combat Waste

From Saved Grams to Substantial Gains: The Tangible Economics of Material Efficiency

The Green Bottom Line: Why Saving Material is True Environmental Stewardship

A Tale of Two Workshops: Traditional Methods vs. Modern Precision

Real-World Impact: Voices from the Factory Floor

Where Does Your Precious Metal Go? Pinpointing Material Loss in the Processing Chain

To solve a problem, you must first understand its source. In metal granulation, material loss is not a single point of failure but a series of vulnerabilities throughout the traditional workflow. Identifying these weak points is the first step toward building a more robust and profitable process.

- The Problem of Incomplete Melting:In many conventional setups, achieving a perfectly uniform melt is a challenge. Uneven heating can leave behind solid or semi-solid metal sediment in the crucible, known as slag or dross. This residue is not pure metal and is often discarded as waste or requires extensive, costly reprocessing to reclaim any value. Each batch with incomplete melting represents a direct loss of raw material.

- The High Cost of Manual Handling:The physical act of transferring molten metal is fraught with risk. Manual pouring, even by a skilled operator, inevitably leads to spillage and splashing. Molten metal droplets can fly out of the crucible, landing on the floor or work surfaces, where they are difficult or impossible to recover. Furthermore, a significant amount of metal can adhere to the walls of the crucible after pouring, creating a residual film that adds up to substantial losses over time.

- Oxidation: The Invisible Thief:When metals are heated to high temperatures in the presence of air, they react with oxygen in a process called oxidation. This chemical reaction creates a layer of metal oxide on the surface of the melt. This oxide scale is not the pure metal you started with; it is a form of waste. For metals like silver and copper, oxidation can be aggressive, visibly reducing the yield. For precious metals like gold, even a small amount of oxidation can affect purity and weight, leading to significant financial losses.

- Thermal Inefficiency and Rework:Temperature control is everything. Overheating the metal can cause some elements to vaporize, literally turning your valuable material into thin air. Underheating results in a viscous, unpourable melt, leading to the incomplete melting problem mentioned earlier. Both scenarios often require the entire batch to be cooled, cleaned, and re-melted. This rework doesn't just consume more time, energy, and labor; it exposes the metal to another full cycle of potential splashing, oxidation, and residual loss, compounding the waste.

The Technological Shield: How Modern Granulators Combat Waste

Understanding the problem is half the battle; the other half is deploying the right tools. Modern granulation machines are not simply furnaces; they are highly engineered systems designed specifically to counter each point of material loss with advanced technology.

- High-Frequency Induction Heating:Advanced systems use high-frequency induction instead of external flames or slow resistance coils. This technology creates an electromagnetic field that heats the metal directly and evenly from within, resulting in fast, uniform, and clean melts. By quickly reaching the target temperature, it reduces oxidation and eliminates un-melted sediment.

- Precision PID Temperature Control:Top-tier granulators use Proportional-Integral-Derivative (PID) temperature control to combat thermal inefficiency. This feedback system constantly monitors metal temperature and makes micro-adjustments to power output, keeping it within ±1°C. This ensures perfect viscosity for pouring, avoiding overheating, underheating, or costly rework.

- Controlled Atmosphere Environments:The best way to prevent oxidation is to remove oxygen. High-end granulators achieve this by creating a controlled atmosphere in the melting chamber, either through vacuum or inert gas like argon. This protects the molten metal, resulting in a purer, heavier final product with minimal oxidation loss.

- Automated and Enclosed Discharge Systems:Modern machines use automated tilting or discharge mechanisms for pouring. The sealed system ensures smooth, computer-controlled flow rates, eliminating splashing and spillage. This precision guarantees every drop of molten metal reaches the granulation tank efficiently.

From Saved Grams to Substantial Gains: The Tangible Economics of Material Efficiency

The financial implications of saving material are staggering. Let's consider a practical scenario for a jewelry manufacturer working with gold. Assume the price of gold is approximately $65 per gram. If a traditional process results in an average loss of just one gram per 10kg batch due to a combination of oxidation and spillage, and the workshop runs one batch per day, the annual loss amounts to over $23,000.

By implementing a modern granulation system that reduces this loss to just 0.1 grams per batch, the annual savings would be over $21,000. For a high-volume refiner or a mint, these numbers scale up dramatically, potentially reaching hundreds of thousands of dollars in saved material cost per year.

For a small precious metal recycler, this efficiency is even more critical. Their business model is built on maximizing the yield from scrap material. Every recovered gram is pure profit. A technology that increases their overall recovery rate by even a small percentage can fundamentally change their profitability and competitive standing. Investing in an efficient machine ceases to be an expense; it becomes an engine for generating higher returns. Any professional metal granulator supplier will emphasize that the return on investment is not just a feature but the core value proposition.

The Green Bottom Line: Why Saving Material is True Environmental Stewardship

The benefits of material efficiency extend far beyond the balance sheet. In an era of increasing environmental awareness and regulations, saving material is one of the most impactful forms of green manufacturing.

This concept ties directly into the principles of the circular economy and carbon reduction. Every gram of metal that is saved is a gram that does not need to be mined, transported, and refined from raw ore—all of which are incredibly energy-intensive and carbon-heavy processes. By reducing waste at the granulation stage, you are effectively reducing the carbon footprint of your entire supply chain.

Furthermore, a more efficient process consumes less energy. Eliminating rework means less electricity or gas is used for reheating. A faster, single-cycle process means the machine runs for fewer hours. This reduction in energy consumption directly translates to lower greenhouse gas emissions. Clean, enclosed systems also mean fewer fumes and a safer working environment. In this light, a highly efficient granulation process is a powerful statement of corporate social responsibility.

A Tale of Two Workshops: Traditional Methods vs. Modern Precision

Imagine two workshops. The first uses a traditional, open-air crucible heated by a gas torch. The operator relies on experience to judge the temperature, the pour is done by hand, and a visible plume of smoke—evidence of oxidation—rises from the melt. Material loss is accepted as a standard cost of doing business.

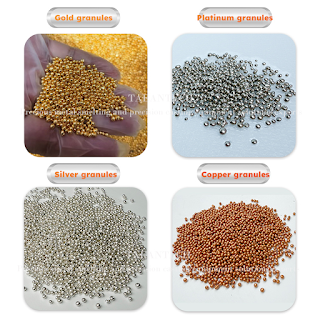

Now, imagine a second workshop. A sealed, automated machine hums quietly. The operator sets the precise temperature on a digital display. Inside, the metal melts quickly and cleanly under a protective argon atmosphere. With the push of a button, the crucible tilts smoothly, pouring a perfect stream of molten metal into the granulation chamber below. There is no splash, no smoke, and no guesswork. The resulting granules are bright, clean, and uniform.

The difference is not just aesthetic; it represents a fundamental shift in philosophy from an art based on approximation to a science based on precision. Reputable suppliers in this space understand this distinction. A quality granulating machine supplier is not just selling a piece of equipment; they are providing a pathway to the second workshop—one defined by predictability, quality, and profitability.

Real-World Impact: Voices from the Factory Floor

While specific data is proprietary, the feedback from businesses that have made this technological leap follows a consistent theme. A jewelry casting house reported that their previously accepted 1% melt loss on 14k gold alloys dropped to less than 0.2% after upgrading their system, leading to a rapid return on their investment. A copper recycler noted that the purity and consistency of his granulated product improved so dramatically that he could command a higher price from buyers, opening up new markets for his material. Another small-scale gold refiner shared that the confidence in his yield allowed him to offer more competitive purchasing prices for scrap gold, growing his intake volume by over 30% in six months. These stories all point to the same conclusion: controlling material loss is a transformative business strategy.

As the industry continues to evolve, the demand for precision and efficiency will only grow. The leaders in this space will be those who recognize that every gram counts. This philosophy is the driving force behind the engineering of today's most advanced systems. For example, a specialized supplier like Taeantech builds its granulating machines around these core principles of material preservation, integrating high-frequency induction heating, precise PID controls, and vacuum and inert gas protection as standard features. By focusing on eliminating the root causes of waste, such technologies empower businesses to unlock their full potential, securing a more profitable and sustainable future, one perfectly formed granule at a time.