In an era of heightened consumer awareness, the materials we choose for food contact applications have never been more scrutinized. From the pots we cook in to the industrial vats that process our food, concerns over plastic leachates, coating degradation, and material longevity are driving a market-wide shift towards safer, more durable solutions. Amidst this landscape, one material consistently rises above the rest: stainless steel. More specifically, the stainless steel circle plate, the foundational component for countless food-grade products, represents the pinnacle of safety, sustainability, and performance. This article delves into the comprehensive advantages of using stainless steel circles in the food industry. We will explore its inherent material properties, its profound environmental benefits, and its crucial role in protecting consumer health. By examining its applications, market relevance, and manufacturing excellence, we will illustrate why this versatile material is not just a choice, but a strategic investment for any forward-thinking brand. For those seeking quality supply, partnering with a trusted stainless steel circles manufacturer ensures unparalleled material performance and long-term reliability.

Table of contents:

Uncompromising Material Properties: The Foundation of Food Safety

The Environmental Imperative: A Champion of Sustainability

Prioritizing Health and Consumer Safety

Versatility in Action: Key Application Scenarios

Aligning with Market Trends and Consumer Demands

The Manufacturing Advantage: Precision and Customization

Uncompromising Material Properties: The Foundation of Food Safety

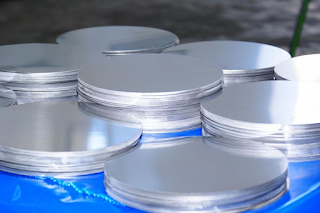

The suitability of a material for food contact begins at its molecular level. Stainless steel’s unique composition gives it a suite of properties that make it inherently superior for any application where hygiene and safety are paramount.

Non-Toxic and Compliant with Global Food Safety Standards

The primary concern for any food-contact material is its potential to migrate harmful substances into food. Unlike certain plastics that may contain BPA or phthalates, or aluminum which can leach into acidic foods, stainless steel is exceptionally stable. Its alloy structure, primarily iron, chromium, and often nickel (in grades like 304), is tightly bonded, ensuring that no harmful elements migrate. This inert nature is why it easily meets and exceeds the world’s most stringent food contact safety standards, including the FDA (U.S. Food and Drug Administration), LFGB (German Food and Feed Code), and GB 4806 (China’s National Food Safety Standards). For manufacturers, using certified food-grade stainless steel is the first and most critical step in building a product consumers can trust.

Superior Corrosion Resistance and Hygiene

The "stainless" quality of steel is derived from its chromium content, which forms a passive, invisible, and self-repairing layer of chromium oxide on the surface. This layer acts as a formidable barrier against rust and corrosion, even when exposed to salts, acids, and alkalis found in various foods. This anti-corrosion property is directly linked to its hygienic performance. The surface of a stainless steel circle plate is non-porous and incredibly smooth, leaving no microscopic crevices for bacteria, food particles, or odors to hide. This makes it remarkably easy to clean and sanitize, a critical feature in both home kitchens and industrial food processing environments where preventing cross-contamination is essential.

Exceptional High-Temperature Performance

Food preparation and processing often involve extreme temperatures, from high-heat searing to industrial sterilization. Stainless steel excels in these conditions. It maintains its structural integrity and chemical stability at high temperatures without warping, degrading, or, most importantly, releasing any volatile organic compounds or chemical fumes. This resilience not only ensures food safety during cooking but also allows for effective high-temperature sterilization methods, making it the material of choice for reusable equipment in commercial kitchens and medical settings.

The Environmental Imperative: A Champion of Sustainability

Beyond immediate safety, modern brands and consumers are deeply invested in the long-term environmental impact of the products they create and use. Here, stainless steel presents a compelling case for sustainability.

High Recyclability for a Circular Economy

Stainless steel is 100% recyclable without any loss of its original quality or properties. It can be collected, melted down, and reformed into new products infinitely, creating a perfect closed-loop system. This process significantly reduces the demand for virgin raw materials and the energy required for their extraction and refinement. By choosing stainless steel, manufacturers contribute directly to a circular economy, turning end-of-life products into valuable resources rather than landfill waste. This stands in stark contrast to most plastics, which have limited recyclability and often end up as persistent environmental pollutants.

Longevity that Reduces Carbon Footprint

The durability of stainless steel translates directly to a longer product lifespan. A well-made stainless steel pot, bowl, or piece of processing equipment can last for decades, if not a lifetime. This longevity drastically reduces the need for replacement, minimizing the resource consumption and carbon emissions associated with manufacturing and transporting new goods. A single investment in a stainless steel product prevents the creation of a dozen disposable or less durable alternatives, making it a powerful tool for achieving a greener supply chain and maximizing resource efficiency.

Controllable and Greener Production Processes

The environmental credentials of stainless steel also extend to its production. Modern steelmaking, particularly through Electric Arc Furnace (EAF) methods, can utilize a high percentage of recycled scrap metal. This process is significantly less carbon-intensive than traditional blast furnace methods. A responsible stainless steel circles manufacturer can further reduce its environmental footprint by investing in low-carbon energy sources and efficient manufacturing techniques, offering clients a product that is green from creation to completion.

Prioritizing Health and Consumer Safety

The health benefits of stainless steel are a direct result of its stable and hygienic material properties, providing peace of mind for consumers, especially those with specific needs.

Zero Harmful Substance Migration

The non-reactive surface of stainless steel ensures that the taste, color, and nutritional value of food remain unaltered. There is no metallic taste and, more importantly, no secondary contamination from the material itself. This makes it the safest possible choice for all food applications, and it is particularly critical for products intended for vulnerable populations like infants and the elderly, such as baby bottle components, food containers, and medical feeding devices.

Easy Cleaning and Disinfection for Bacterial Control

As mentioned, the smooth, non-porous surface of stainless steel is its greatest hygienic asset. It does not harbor bacteria and is exceptionally easy to clean with simple soap and water. For applications requiring absolute sterility, its ability to withstand high-temperature steam, chemical sterilants, and autoclaving processes without damage makes it an indispensable material in healthcare and commercial food production.

Versatility in Action: Key Application Scenarios

The inherent benefits of stainless steel circles make them the starting point for an incredibly diverse range of food-grade products across multiple sectors.

Home Kitchenware and Cookware

This is the most visible application. High-quality pots, pans, mixing bowls, plates, cutlery, and insulated beverage containers are all crafted from circular steel blanks. In this high-contact environment, consumers prioritize health, durability, and aesthetics, all of which stainless steel delivers.

Commercial Food Service and Processing Equipment

On an industrial scale, stainless steel is non-negotiable. It is used for everything from massive mixing vats and conveyor belts in central kitchens to fermentation tanks, cold storage shelving, and precision components in food processing machinery. Its robustness, hygiene, and resistance to harsh cleaning agents are vital for operational efficiency and regulatory compliance.

Medical and Infant Care Products

The highest standards of safety are required for medical and infant products. Food-grade stainless steel is extended to these fields for items like the base of baby bottles, insulated containers for formula, and various medical instruments, where absolute purity and sterilizability are paramount.

Aligning with Market Trends and Consumer Demands

The choice to use stainless steel is not just a technical decision; it is a strategic market move that aligns with powerful consumer trends.

Rising Consumer Consciousness

Today’s consumers are more informed and conscientious than ever. Movements like "plastic-free living" and a focus on "clean eating" and "healthy homes" are driving demand for products made from safe, sustainable materials. Brands that use stainless steel can tap directly into this sentiment, building trust and loyalty.

Fusing Brand Responsibility with Product Philosophy

Leading companies are no longer just selling products; they are selling a philosophy. Incorporating stainless steel allows a brand to build a compelling story around health, sustainability, and quality. This commitment to creating responsible, long-lasting products helps establish a "green brand" image that resonates powerfully with both B2B clients and end consumers.

The Manufacturing Advantage: Precision and Customization

For a product to be great, its foundational components must be perfect. The manufacturing process for stainless steel circles offers a level of precision and customization that empowers designers and engineers.

Customization Value in Food-Grade Products

Every product has unique specifications. A key advantage of working with a specialized supplier is the ability to source custom-cut circles. The process of cutting stainless steel sheet can be tailored to produce discs of any required diameter and thickness, ensuring the perfect starting point for a pot, a lid, or a machine part. Furthermore, surface finishes like brushed, mirror polish, or sandblasted can be applied to meet specific aesthetic and functional requirements.

Precision Manufacturing to Minimize Waste

Modern manufacturing techniques, such as precision shearing or laser cutting, allow for the creation of stainless steel circles with extremely tight tolerances. This accuracy not only ensures a perfect fit in final assemblies but also optimizes the use of the raw material, minimizing scrap and reducing waste. This reflects a commitment to lean and green production management, a quality that is increasingly valued in the supply chain.

The evidence is clear: from its inert, non-toxic nature to its incredible durability and environmental benefits, stainless steel is the undisputed champion for food-grade applications. The circular steel disc is the genesis of products that are safer, last longer, and align perfectly with the values of the modern consumer.For businesses looking to harness these benefits and deliver superior products to the market, the choice of a raw material supplier is mission-critical. Finding a partner that understands the nuances of food-grade materials is key. This is where a dedicated stainless steel circles manufacturer like YIHO GROUP LIMITED becomes an invaluable partner. Specializing in providing high-quality, customized stainless steel circles, including the widely used 304 grade, they are experts at cutting stainless steel sheet to precise specifications. Working with an experienced 304 stainless steel sheet supplier ensures that the very foundation of your product—the stainless steel circle plate itself—meets the highest standards of safety, quality, and performance, empowering your brand to deliver on its promise of excellence.